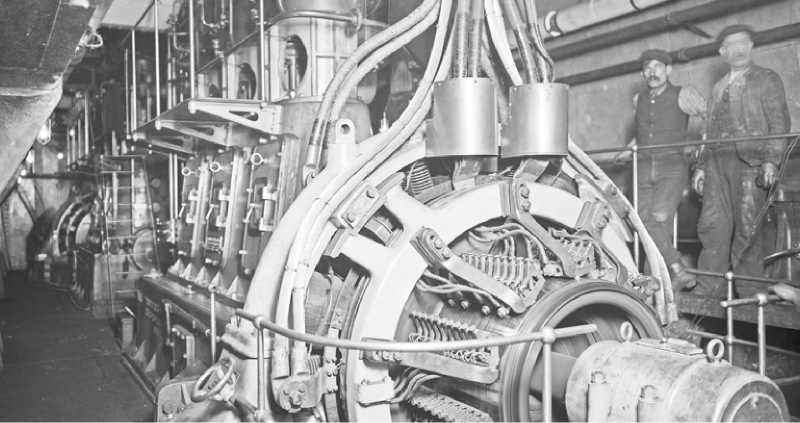

The main generating plant’s four 400-kilowatt dynamos were made by W. H. Allen, Son & Company of Bedford. Combined, they were capable of producing 16,000 amps at 100 volts DC. The four were arranged in two pairs fore and aft, with the crankshafts of each in line. Dynamos 1 and 2 were on the starboard side, 3 and 4 on the port, and they were separated by a maintenance platform. All the dynamos were steam-driven, as were the two emergency sets situated in the turbine engine room, by a set of high-speed reciprocating engines.

The four main dynamos worked in tandem, so they could combine output to deal with increased electrical load when required. The general arrangement was that one generator dealt with the liner’s lighting, and two more with power and heating, while the fourth acted as a backup. Each could be operated at varying speeds, and stopped or started independently of the others. Instructions were communicated to the electrical engineer on duty by means of a signal lightboard in the center of the electrical engine room. The orders start/stop and raise/ LOWER, referring to speed, together with a number indicating which dynamo was meant, gave the engineer all the information he needed.

A detail of Olympic’s starboard main generating set.

The main switchgear was located on the Orlop deck, just above the forward end of the electrical engine room. There were two main circuits, one for lighting and one for general power. The switches had a four-way system to allow any one dynamo to be allocated to any task. When demand was low, for example at night, fewer dynamos were needed, and some could be closed down and placed on standby. Again, specialist firms were subcontracted by Harland & Wolff to supply the necessary machinery. In the case of the switchgear, that firm was Dorman & Smith of Manchester.

World History

World History