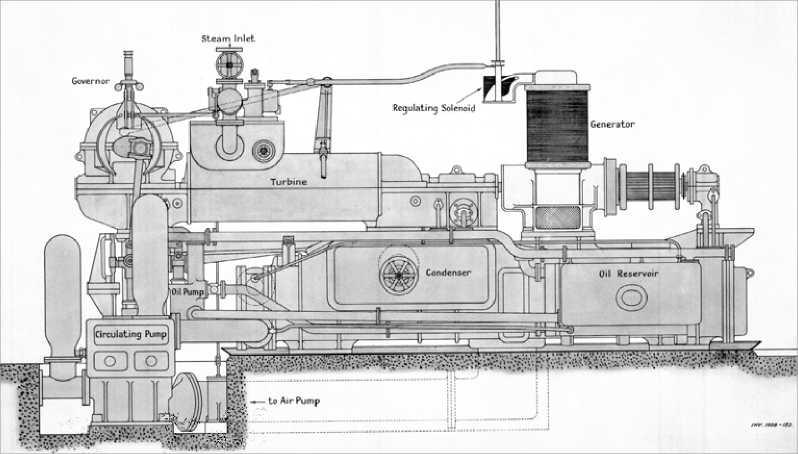

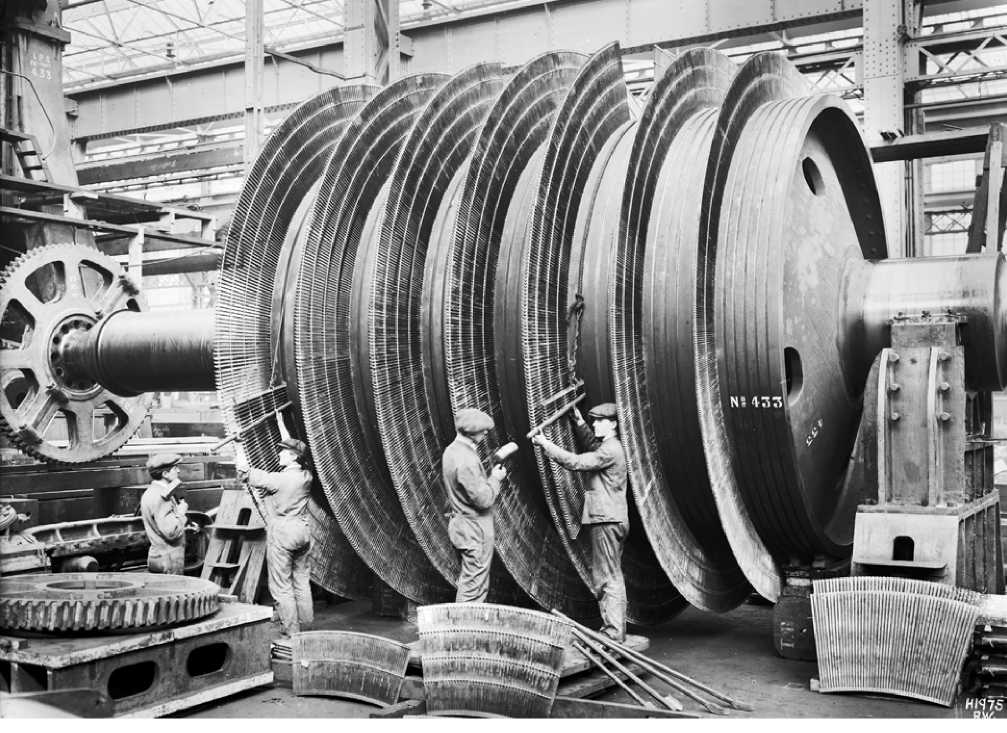

Parsons steam turbine engine of the type used in Titanic. Turbine engines were faster and more efficient than their conventional counterparts.

Among the many innovations that occurred in mechanical engineering at the turn of the nineteenth and twentieth centuries, one that was to have special significance was the marine steam turbine engine. Essentially, a turbine is a rotary engine that extracts energy from a fluid, steam, or air flow and converts it into useful work. The simplest turbines have one moving part, a rotor in the form of a shaft or drum, with blades attached. The propulsive power—water, steam or gas— acts on the blades, or the blades react to the flow, and they move, thus

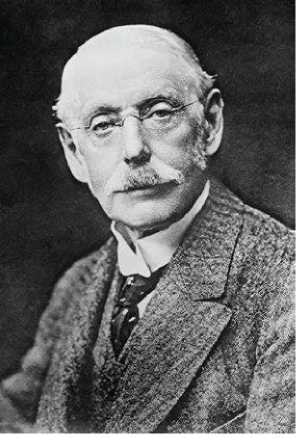

Sir Charles Parsons in later life. His invention of the steam turbine revolutionized marine transport.

It was the steam turbine engine, as a means of ship propulsion, that was to have a truly world-changing effect.

Imparting rotational energy to the rotor or drum. Waterwheels and windmills are simple examples of the principle.

The marine steam turbine was first developed by the thirty-year-old Cambridge mathematics alumnus Charles Parsons in 1884, when he was head of electrical equipment development at a ships’ engine manufacturers near Newcastle-upon-Tyne. He first used his new invention to drive an electrical generator (also his invention), which made the production of cheap electricity possible. This was in itself a massive step forward, but it was the steam turbine engine, as a means of ship propulsion, that was to have a world-changing effect. In 1889 Parsons founded his own company, Parsons Marine Steam Turbine Company, to produce his turbo-generators, and after a modest start, rapid improvements meant that ten years later he had built his first megawatt turbine for a plant at Eberfeld in Germany.

Parsons was not alone in his work with turbines. A close Swedish contemporary, Gustaf de Laval, had also worked on them. His impulse turbine worked by changing the direction of flow of a high-velocity fluid or gas jet. This, however, subjected the machine

To powerful centrifugal forces. As the materials then available could not withstand the forces put on them, the impulse turbine had limited output. Parsons’s reaction turbine developed torque (twisting movement) by reacting to the pressure or mass of the gas or fluid: gas, steam and water turbines have a casing round the blades, which contains and controls the propulsive agent. The Parsons type needs twice the number of blades as the Laval type, which makes it longer and heavier, but more efficient.

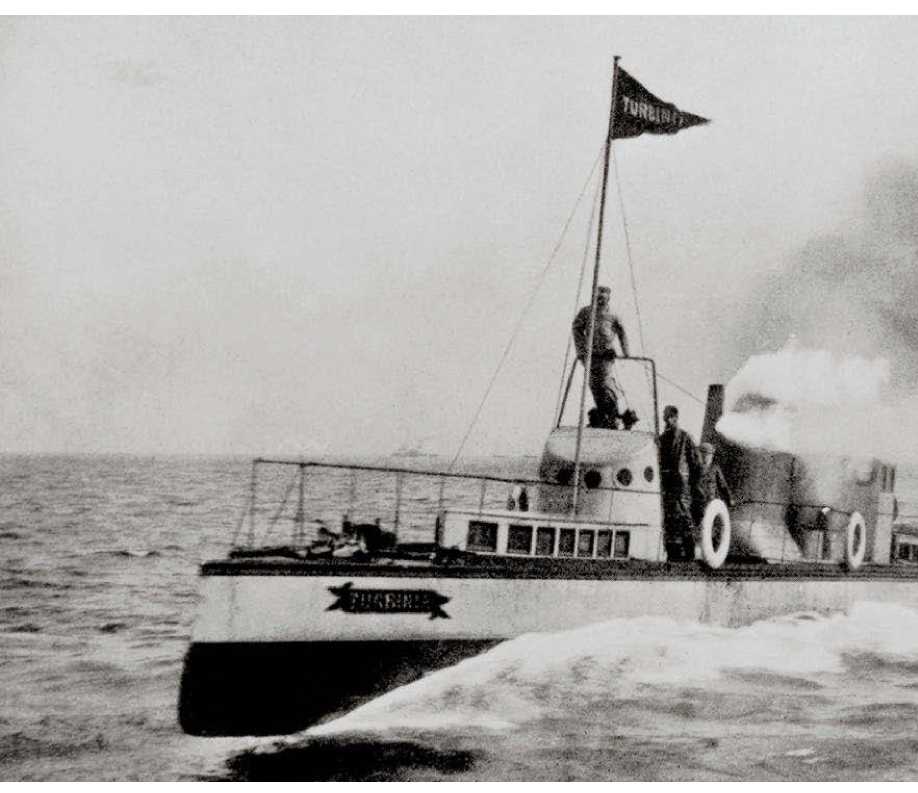

Parsons's wonderful-looking yacht,

Turbinia. He showed her off—uninvited— at the 1897 naval review at Spithead and astonished professional seamen by achieving a speed of 34.5 knots in her. Orders for turbine engines for ships— especially warships— quickly followed.

Parsons’s ideas were as diverse as they were interesting. Among his inventions was a steam-driven helicopter that lifted itself several feet into the air—a huge achievement in 1893, when most engineers dismissed the possibility of mechanical flight. In 1895 he constructed a model monoplane that rose 20 feet into the air and flew for 80 yards. His auxelophone, for amplifying musical and vocal sounds without the distortion inseparable from reproduction by a mechanical diaphragm, was adopted by the conductor Sir Henry Wood and used at concerts at the Queen’s Hall, London, in 1896. He also invented the first non-skid

Motor tires and a means of creating diamonds artificially by crystallizing coal.

In June 1897, the year of Queen Victoria’s Diamond Jubilee, he showed off his yacht Turbinia near Portsmouth during Her Majesty’s Jubilee Fleet Review. Turbinia could make 34 knots—7 knots faster than the fastest warship then afloat, though part of the speed was due to the boat’s slender lines and relative lightness. He was made a member of the Royal Society in 1898.

Within two years, the new destroyers HMSS Viper and Cobra had been launched, each equipped with Parsons’s turbines. The first turbine-powered passenger ship, a Clyde steamer, TS King Edward, appeared in 1901, and the first battleship, Dreadnought, followed in 1906. Parsons was awarded the Rumford Medal of the Royal Society in 1902, and (although already the son of an earl) was knighted in 1911 and made a member of the Order of Merit in 1927. His company still exists in Heaton, Newcastle, but is now part of the Siemens group.

Parsons may subsequently have regretted letting the Germans know the secret of his invention. Von der Tann, Germany’s first battle cruiser, was laid down on 25 March 1908 and launched a year later on March 20. She was built by Blohm & Voss (now part of ThyssenKrupp) of Hamburg, and was powered by two Parsons turbines.

The engine that drove Titanic’s central propeller was a Parsons turbine as well, but in those days the turbine, though it already displayed considerable power for its size and weight, was yet to become an economically viable replacement for the reciprocating (or piston) engine.

Cunard, however, in pursuit of speed, had decided to switch to turbines in 1904, and the Lusitania and Mauretania were both equipped with them, the Mauretania being at the time of her first

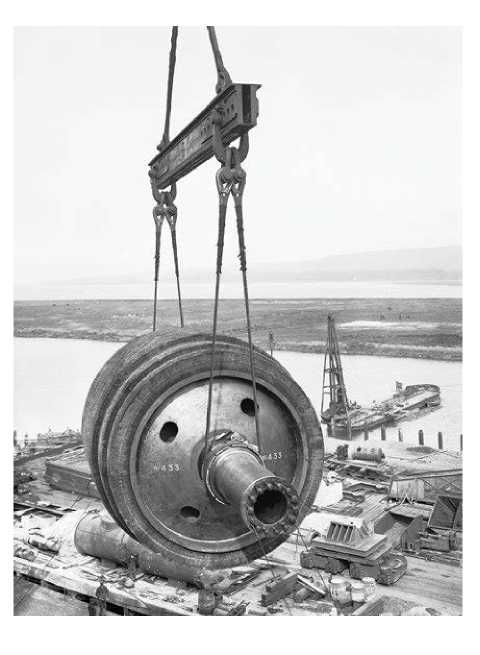

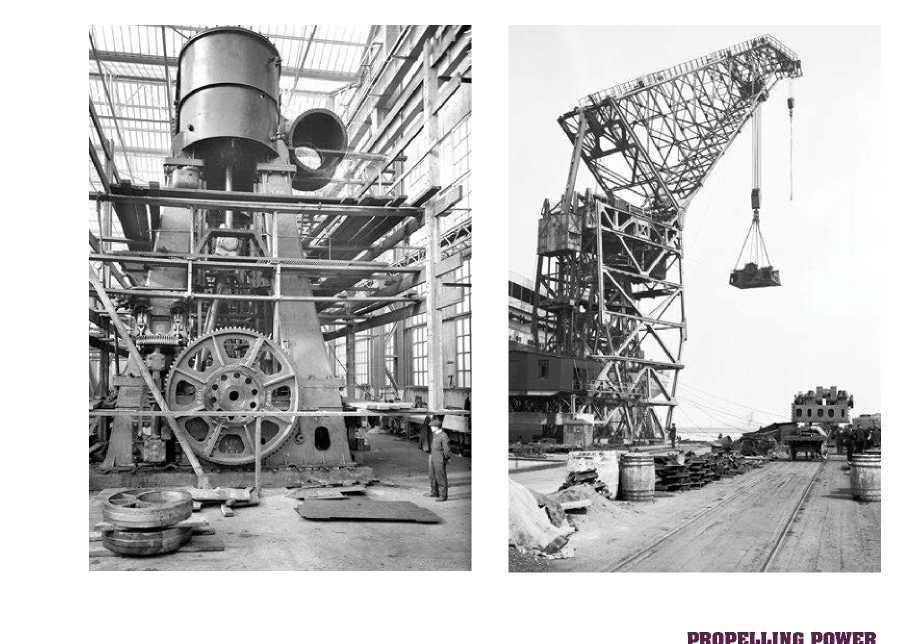

The rotor for Britannic's turbine is lifted aboard her by the 200-ton floating crane.

Voyages the largest application of this new technology to date. (The two sister ships were the only ones to win the Blue Riband for Cunard and, indeed, Britain during the opening decades of the twentieth century.) However, during trials, the turbines caused significant vibration at high speeds; in response, the Mauretania was fitted with strengthening members and redesigned propellers before entering service, which reduced the problem.

While White Star was more concerned with economy, luxury and reliability than speed, they nonetheless wanted to keep vibration to a minimum, so they compromised and stuck to the reciprocating engine for Titanic’s main power, installing one for each of the wing propellers. But it was clear to the engineers at Harland & Wolff that the kind of power needed to drive a liner of Olympic-class size at over 20 knots (the Mauretania could make 25, Titanic 23) was beyond even the largest reciprocating engines, and they were aware of what Cunard had already achieved. So they met the innovation almost halfway: they’d have three engines, but only one of them would be a turbine.

Harland & Wolff had already obtained a license to build Parsons engines in 1905, but since then, largely for economic reasons, had done little to implement production. Lacking both the necessary plant and expertise, and faced with a sudden need to produce turbines, it made a generous merger offer to John Brown & Company of Clydebank, who had built the Lusitania. The offer was accepted, and Harland & Wolff was therefore able to access John Brown’s turbine technology and workshops, as well as a number of other assets belonging to that

The Olympic-class liners had one central turbine engine in addition to their two reciprocating engines. Here, workers are seen fitting the blades to the turbine rotor.

Company. Following this, Harland & Wolff’s engineers designed the turbines, which were made by John Brown, and then taken to Belfast for final machining and assembly.

Titanic’s turbine was designed to take steam from the two reciprocating engines at 9 lb psia (per square inch absolute). It was among the biggest marine exhaust turbines ever made (only that of Britannic, her younger sister, was larger): it was 50 feet long, weighed 410 tons, and delivered, when running at 165 rpm, about 16,000 shaft horsepower.

In fact, the combination of reciprocating and turbine engines was a huge success. It had been tried out on two smaller, earlier sister liners, Megantic and Laurentic, in the sense that Megantic was conventionally powered, but Laurentic was fitted with two reciprocating engines placed port and starboard, and a single turbine centrally placed aft of them, which was driven by exhaust steam.

CAUGHT AT SEA

New technology helped both Megantic and Laurentic to play a role in the dramatic pursuit and arrest of the murderer Hawley Crippen in 1910. Crippen had set off for Canada with his mistress on the SS Montrose, after having aroused the suspicions of Scotland Yard in connection with the death of his wife. Unfortunately for him, Montrose’s captain recognized the fugitives. Even more unfortunately, Montrose was equipped with a Marconi radio, and the captain had a wireless telegram sent to the British authorities:

Have strong suspicions that crippen London cellar murderer and accomplice are among saloon passengers. moustache taken off and growing beard. accomplice dressed as a boy. manner and build undoubtedly a girl.

Had Crippen traveled third class, he might have escaped the captain’s notice. Chief Inspector Walter Dew of the Yard boarded a faster White Star liner, Laurentic, arrived in Quebec ahead of Montrose, and contacted the Canadian authorities. He arrested Crippen on the latter’s arrival, and the guilty man was taken back to England on Megantic to be hanged. As Laurentic was able to pass Montrose, it might be said that the turbine engine also played a part in Crippen’s downfall.

Laurentic’s performance was successful and confirmed Bruce Ismay’s already solid belief in Lord Pirrie and Harland & Wolff. Work on the new superliners was able to proceed (indeed it was confirmed even before Laurentic’s maiden voyage) using the same engine configuration and combination, though of course on a much larger scale, as that employed on Laurentic. Ismay’s faith paid off. At the end of

This iconic picture is of a masked Hawley Crippen (right) being escorted off the Montrose following his arrest by the bowler-hatted Walter Dew (left).

Opposite left:

Titanic’s port reciprocating engine in the workshops before being installed aboard.

Opposite right:

One of the engine bedplates being transferred aboard by the enormous floating crane.

Olympic’s maiden voyage, Ismay, who had traveled on her—as was his frequent habit on maiden voyages—cabled excitedly to Pirrie:“oLYMPic is a marvel, and has given unbounded satisfaction. once again accept my warmest congratulations.” Olympic had indeed not only lived up

The two reciprocating engines were giants. Each was 63 feet long and weighed 720 tons.

To, but exceeded, expectations: the voyage had taken precisely five days, fifteen hours and two minutes, at an average speed of 21.7 knots. And her fuel consumption had been gratifyingly low: just 3,540 tons of coal.

The two reciprocating engines were giants. Each was 63 feet long and weighed 720 tons. They would have been lowered into the hull using the floating crane, the only machine big enough for the job, and installed by a workforce of at least one hundred men. The bedplates they were placed on each weighed an additional 195 tons. Along with its own fully

Equipped workshop, their engine room was sited immediately aft of the aftermost boiler-room, between watertight bulkheads K and L. It was 69 feet long. Either side of the engines, ancillary equipment was arranged. The turbine engine room was next aft, between bulkheads L and M, and took up a further length of 54 feet. As well as the turbine, this room contained, among other things, the main condensers, the evaporators and distilling plant (for the production of fresh water, taking vapor from the evaporators), and several pumps for bilge and other purposes. Next aft was the electric engine room, which housed the four 100-volt DC main generating sets, which ran another 66 feet aft to watertight bulkhead N. The tube for the shaft of the central propeller passed through here, through the next compartment and the last bulkhead (P), after which it left the hull. The propellers would be mounted in dry dock after the general fitting-out.

Built of steel throughout, and for passenger traffic only, [T/tan] carried no combustible cargo to threaten her destruction by fire; and the immunity from the demand for cargo space had enabled her designers to discard the flat, kettle-bottom of cargo boats and give her the sharp dead-rise—or slant from the keel—of a steam yacht, and this improved her behavior in a seaway. She was eight hundred feet long, of seventy thousand tons displacement, seventy-five thousand horse-power, and on her trial trip had steamed at a rate of twenty-five knots an hour over the bottom, in the face of unconsidered winds, tides, and currents. In short, she was a floating city—containing within her steel walls all that tends to minimize the dangers and discomforts of the Atlantic voyage— all that makes life enjoyable.

Futility or The Wreck of the Titan, a prescient novella by Morgan Robertson, 1898

Double-ended boilers lined up in the workshops ready for transfer aboard an Olympic-class ship. Their colossal size can be judged from the man standing about halfway down the row.

World History

World History