Of all the different variations of the horn composites, the best known are the Turkish flight bows described in the writings of Klopsteg who, as an archer, mathematician, and engineer, reviewed the German translations of Hein of the original sixteenth century Arabic treatise of Kani.

The use of the bow for warfare in Asia waned about five hundred years ago, but the sport of archery was kept alive in Turkey by competitive shooting for distance. The old field of competition, the Ok Meidan, exists to this day in Istanbul. Thus the majority of composite horn bows still available for study and examination are the flight bows, about two hundred years old, rather than the war bows. Examples of the earlier heavy war bows such as the Crimean Tartar are occasionally seen. They are fifty to sixty inches long as compared to the forty-four or forty-five inch flight bow. The heavier bows also have a small added pad made of bone, ivory or wood at the angle of the recurve for the string to rest on when the bow is braced and during the early part of the draw.

The flight bows were designed to take advantage of the maximum tolerance of the horn, wood, sinew, and glue to the stresses applied during use. Some bows are still intact after two hundred years, speaking well of the meticulous construction which often required four years from start to finish.

Theoretically, the most efficient bow is one in which the string rests on the face of the bow at the braced position, gradually lifting off of the tip during the draw — the recurved bow. Since the force of the string has the least effect on the limb when parallel to it (in contact) and the most effect when at right angles to it, the configuration and flexing of the bow limb should be such that the string is at 90 degrees to the tip of the limb at full draw, and in contact with as much of the limb as possible at brace position. A further concern is that there should be

Old Turk flight bow, relaxed shape, 45" long. About 200 years old, varnish only over sinew back.

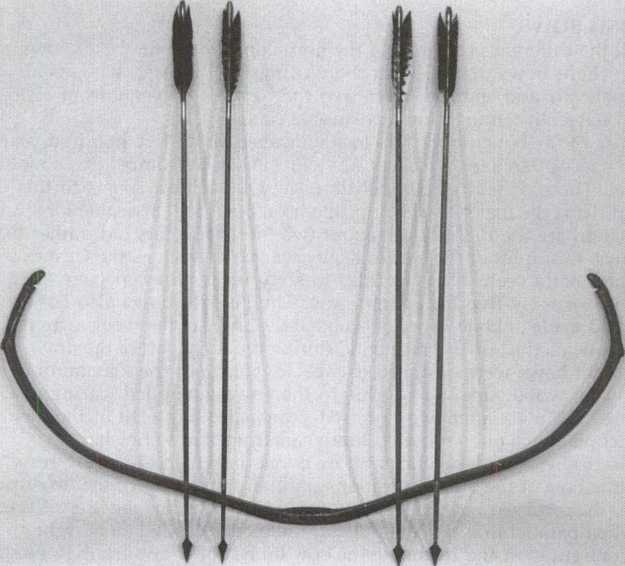

Crimean Tartar bow, signed and dated, about 200 years old. Red leather covering with gold floral design. Horn on face left uncovered. 62" long. Arrows 35" long.

Uniform stress, compression, and tension throughout the limb at full draw. For this to apply, the thickness of the limb should be the same throughout, but the limb would diminish in width toward the tip. The ideal limb shape would be an arc of a circle at rest and a straight line at full draw, with the bow string at right angles to the bow tip. Such a bow would be deflexed at the center as an angular bow. The bow would be efficient but, in fact, unstable, tending to twist and "un-string" in the hand during draw or release.

The Turkish bows included some of these attributes but not enough to cause more than a minimal amount of instability. There existed almost no reflex at the center. The reflex curve was long and blended smoothly into the recurve. Though the string contacted the surface of the limb for only a short distance at brace height, it lay parallel to the limb enough to shorten the effective length during the first part of the draw. Also, the limb flexed almost entirely in the middle third, so the string was at right angles to the tip at full draw, a simple principle of leverage.

The Turkish bow was built on a wood core usually of five pieces joined together by dovetail or "V" joints. The center section, about eight inches long, an inch thick, and three-fourths inch wide, also served as a grip with a riser on

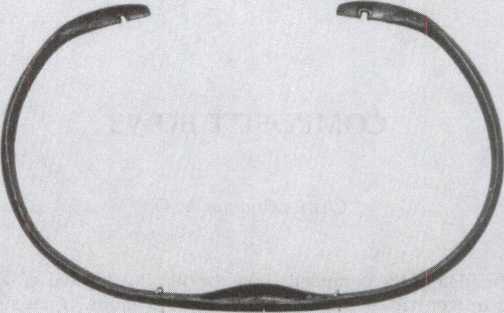

X-section at center

X-section at mid-limb

X-section at knee

Cross-sections of Turkish flight bow.

Back. Limb sections were flat, about an inch wide and one-fourth inch thick and fifteen inches long. Notches cut on the outer end of each accepted the long tips, or siyahs, glued in at an angle to form the recurve. They were left thick to allow for subsequent carving of all ridges. All five pieces were carved to blend smoothly together.

Before any further tapering, the bowyer deeply grooved the front face with a tool like a coarse wood saw blade with teeth about twelve per inch. About one twelfth inch deep, the grooves formed a 60-degree angle. A strip of horn for the belly was identically grooved to fit the wood grooves. This grooving doubled the area of glued surface and altered the force of separation from a direct pull to a shearing force. Of all the old Turk bows I've examined, none showed any sign of separation of this glue joint.

The horn was glued to the wood and compressed by wrapping with a special cord into which a short tool was inserted and twisted, which acted as a lever. Wayne Alex, Alaska, says he can obtain enough pressure to deform the wood in the grooves with this method if there is not an exact fit. Even clamps will not exert this much pressure, nor will they provide such evenly distributed pressure.

Usually a gap of about a sixteenth of an inch existed between the ends of the horn strips at the center. Whether left purposely or the result of further reflexing of the bow, this gap is not explained. It was filled with a narrow piece of bone or ivory to help prevent splaying of the horn when the belly was subjected to tremendous compression during a shot. A fifty pound bow with two foot limbs and a one inch thick (front to back) grip will undergo about 2500 pounds of compression on the belly. The sinew back undergoes a similar degree of tension, if the neutral plane is halfway between the front an back of the bow (keep in mind that the sinew and horn nearest the surface perform most of the work). Horn tolerates about 4000 pounds of longitudinal compression before collapsing. Antler is less tolerant, depending upon its age and treatment during processing.

In preparation for the sinew backing, the bowyer reflexed the bow by tying a cord between the nocks. The sinew, extracted from the back legs of cattle, was dried, pounded, shredded and set aside in bundles. Scrap pieces of tendon, simmered for several days, yielded the glue. Fish glue and hide glue were sometimes added to the sinew glue.

Glue soaked bundles of sinew were applied to the back of the bow, beginning at the grip and extending outward to the siyah, each succeeding bundle overlapping the preceding one. The bowyer combed the sinew to make the fibers straight and parallel. The first layer of sinew was allowed to dry, the bow reflexed more and held in place by the cord while another layer was added. The bowyer increased the reflex with each added layer of sinew until the bow tips touched or crossed.

The Turks allowed the sinew to dry for six months or a year before tillering and finishing the bow. On some bows the horn was scraped down to the wood core near the tips during tillering, so that the grooving could be seen. A horn faced bow could also be balanced for even tiller by heating the horn on the belly. The bow tips were narrowed to about a half inch for a distance of three or four inches. The bow string had a long loop that lay on each side of this segment

Turkish replica by Helmut Mebert, about 1940. Composite, thin rawhide covering, 47" long.

Down to the knee, where the connecting knot rested on the front surface of the limb or on the bridge, if present. As the bow was drawn, the string lifted away from the recurve and lengthened the effective portion of the limb while the angle between the string and the tip increased. The central part of the bow showed little reflex, since the distribution of sinew over the riser limited flexing in this area. Most of the bending occurred in the middle third of the limb, which resulted in a reflexed, recurved bow that was the ultimate in combination of efficiency and stability. The result of this configuration is best demonstrated in the energy storage graph of the Chinese bow, to follow.

How far would the finished bow cast an arrow?

Using the thumb draw, a special barreled arrow of twenty-five inches, and a four inch overdraw, ancient stone markers indicate distances over nine hundred yards!

About fifty years ago, a German, Helmut Mebert, created replicas of Turk bows as well as replicas of other Asiatic bows that, with some minor repairs, are still usable today. Today, Edward McEwen, Wayne Alex, Jeffrey Schmidt, and others are constructing composites following details of the old bowyers.

The best flight bows were "conditioned" by warming, presumably to dry out the sinew. It would be interesting to determine whether the warming and drying process really shortened the sinew backing or allowed the horn facing to expand to its original length.

The question of which is the best natural material or combination of natural materials in making composite bows is far from being answered. More testing and experimentation needs to be done, much as synthetic bow materials have been researched.

World History

World History